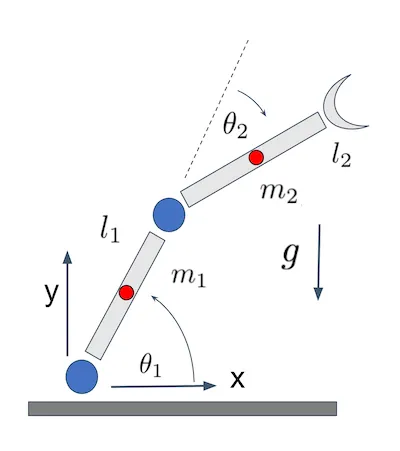

Equations of Motion of a 2-DOF Planar Robotic Manipulator

Consider a planar 2-DOF robotic arm with constant link lengths

Kinematics for the Robot Arm Links

The position of the center of mass of the first link reads

where

which accounts for the fact that the second arm is attached to the first and that we have another generalized coordinate,

Kinetic and Potential Energy

In order to construct the Lagrangian

Here, the squared velocities of the centers of mass of both links via

Since we also consider rotational kinematics we have to account for the change in the kinetic energy due to the rotation of each link about its center of mass. The corresponding angular velocities read

The potential energy is:

Euler Lagrange Equations

The main idea is that the Euler–Lagrange equations result in the equations of motion for the links. To control that motion, external torques

where

where

The Inertia Matrix

In our example of a two link robotic arm, we have two generalized coordinates

and thus the inertia matrix

Those are

Note that this matrix changes with the configuration of the robotic arm.

Coriolis and Centrifugal Terms

A common form of the velocity-dependent matrix

where

Final Equations of Motion

The final equations of motion read

Trajectory Planning

To move the robotic arm smoothly from its initial configuration to the target configuration, we plan trajectories for the joint angles

A common, even though somewhat counterintuitive approach is not to solve the equations of motion for the joint angles but to assert that all angles must behave in a way that smooths transitions between the initial and final positions.

In other words, we postulate that a joint angle

The coefficients

The time evolution of the joint angles is given by

and angular velocities and accelerations follow by differentiation:

With the joint velocities and accelerations known, the required joint torques

by substituting

Numerical Example

Let us consider the an example with the following parameters:

- Link lengths:

, - Initial end-effector position:

, - Desired end-effector position:

, , , , , the gravitational acceleration on Earth at sea-level ,

where

Step 1: Solve the Inverse Kinematics

First we need to calculate the value of the generalized coordinates at the initial and final times.

To achieve the desired end-effector position

we can derive

and find the joint angles

Here,

Step 2: Boundary Conditions

Suppose we plan to reach the target configuration in

Then, based on the inverse Kinematics we have

Since we also want the arm to be at rest before and after the maneuver we add

where all values have units of rad/s.

Step 3: Compute Velocities and Accelerations

The joint angles should follow a cubic polynomial trajectory:

From the boundary conditions we can compute the coefficients for

The boundary conditions

Since we know

in units of rad/s

Following a similar path, we find the coefficients for

The final equations for the joint angles and their derivatives in units of rad, rad/s and rad/s

Step 4: Compute Required Torques

We can now compute the torques

This results in

Inserting the polynomials for